Get Started on Your SNAPP screen Project

Nothing beats the ability to enjoy the outdoors without being bothered by nuisance insects. A screen porch, patio, or deck adds value to your property and, thanks to the SNAPP screen Track system, is easier than ever to install yourself! Here’s what you need to get started:

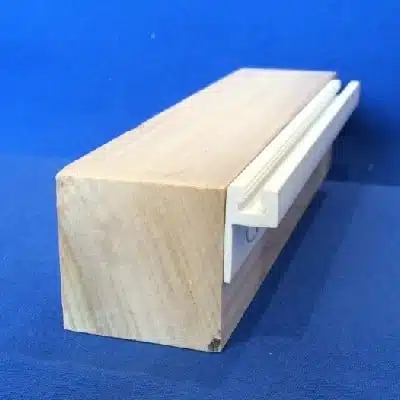

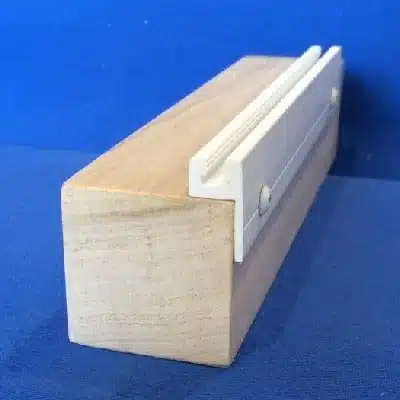

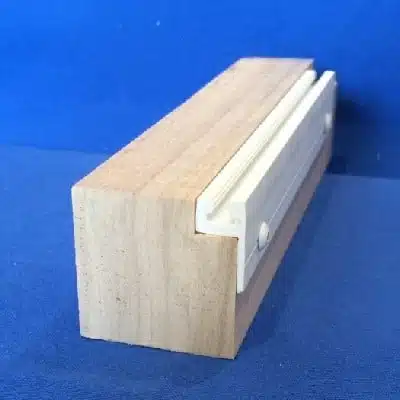

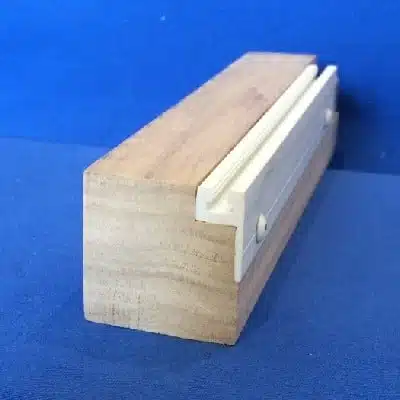

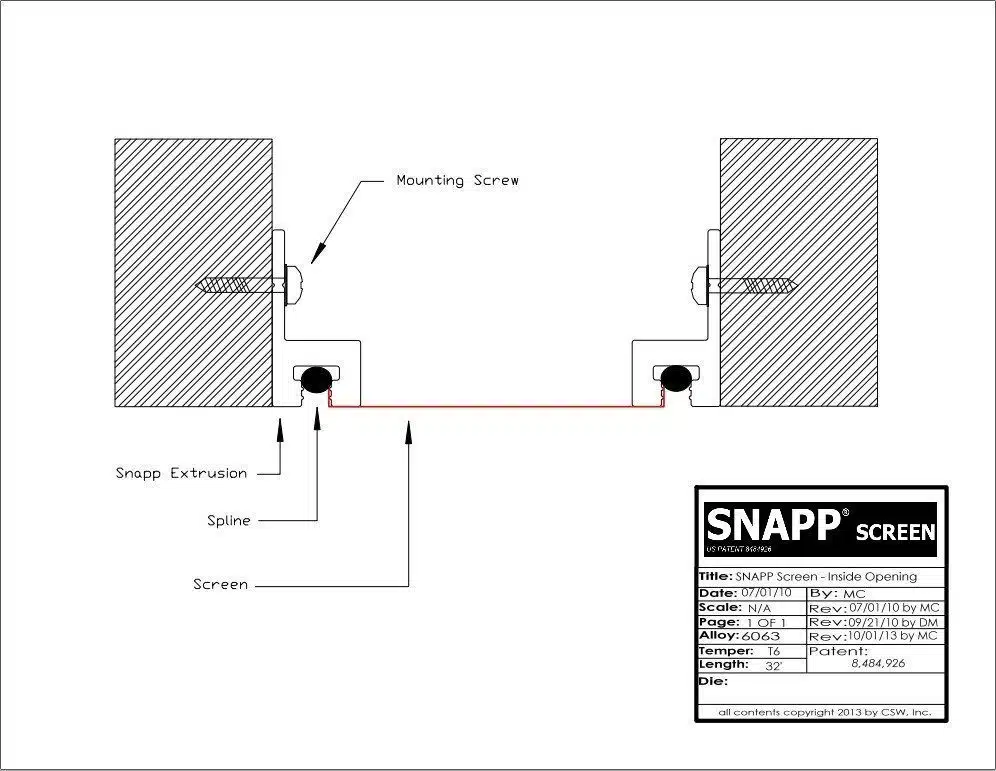

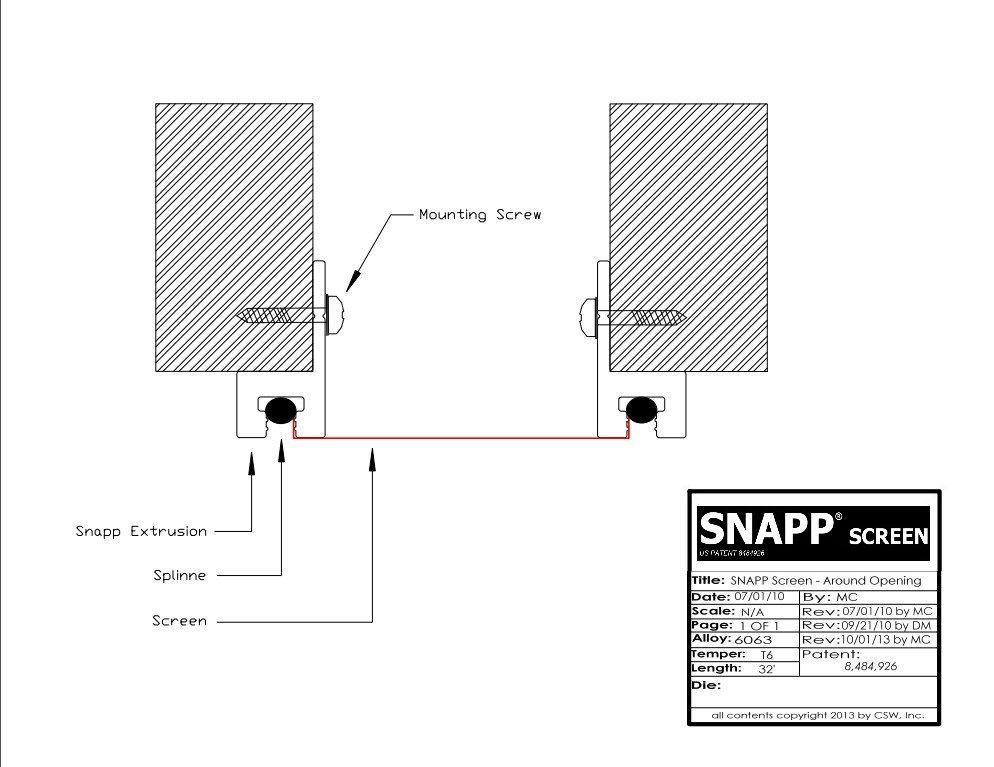

Snapp screen Track Mounting Options

Basic Installation Instructions

- Cut SNAPP screen extrusion to size and mount in place. (SNAPP screen is a zero-waste product … extrusions can be butted together)

- Fasten with screws or other appropriate hardware. Hardware is placed within 1″ of each end and then no more than 12″ apart thereafter.

- Install SNAPP screen Polyester Screen Material (or any standard fabric screen materials) using SNAPP screen spline and SNAPP screen spline installation tool.

Full Step by Step Instructions – How to install SNAPP screen

Modify all directions as needed based upon your application

Step 1

Determine the materials you’ll need to order

- SNAPP screen extrusions

- SNAPP screen mounting screws

- SNAPP screen spline

- SNAPP screen spline tool

- SNAPP screen screen material

Step 2

Ensure you have the proper tools available

- Measuring Tape

- Utility knife (with extra blades)

- Screw gun

- Spline Installation Tool

- Hacksaw or power chop saw fitted with an aluminum/plastic cutting blade. (We find the Freud Diablo series aluminum/plastic cutting saw blade to be one of the best to use – 80 or 96 tooth – based on blade size required. Available at any home center)

Step 3

Determine how you intend to mount (“inside” or “around” opening) (“miter” or “butt” corners)

Mount Inside Opening – Butt Corner

Mounted inside the opening with butt corner. Mount facing outwards, inwards, or at any depth within the opening.

Mount Inside Opening – Miter Corner

Mounted inside the opening with miter corner. Mount facing outwards, inwards, or at any depth within the opening.

Mount Around Opening – Butt Corner

Mounted around the opening with butt corner. Mount on the exterior or interior.

Mount Inside Opening – Miter Corner

Mounted around the opening with miter corner. Mount on the exterior or interior.

Inside The Opening

As the installation name implies, the extrusion is installed within or “inside” the opening. The extrusions can be mounted at any point within the opening provided enough room exists for screen installation. The extrusion can face interior or exterior and the installation can be with miter or butt corners (or a combination of both if required).

Around The Opening

When installing the extrusion “around” the opening, the extrusion head will be located outside of the opening itself. This gives a picture frame effect, or reveal, which tends to be complimentary to most installations. The extrusion can face interior or exterior and the installation can be with miter or butt corners (or a combination of both if required).

Step 4

Width extrusions

- Measure the width dimensions and cut extrusion to proper size

- Test fit in your opening then predrill for mounting screws (Use the score line to position drill holes)

- Place hole 1” from each end and then no more than 12” apart

- Install the width extrusions

Step 5

Height extrusions

- Measure your height dimensions and cut extrusion to proper size

- Test fit in your opening then predrill for mounting screws (Use the score line to position drill holes)

- Place hole 1” from each end and then no more than 12” apart

- Install the height extrusions

Step 6

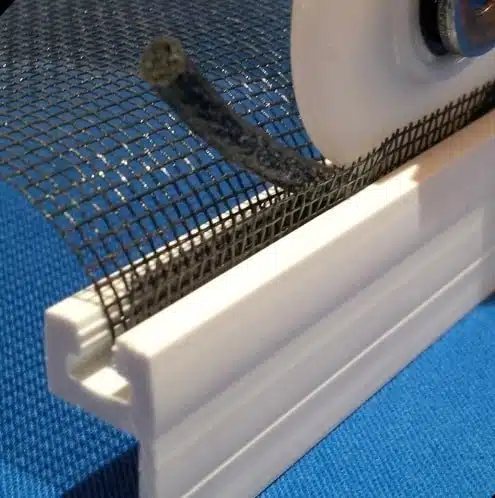

Screen Installation

- Screen installation is similar to traditional screen rolling

- Watch Screen Installation Video (below) for complete screening instructions

- Fabric screening (polyester, fiberglass, etc.) is recommended. Avoid metal screening

- Screening pattern is top, bottom, prime hand side, non-prime hand side

- Use only SNAPP screen spline tool or 3/32″ nylon equivalent

- Use only new SNAPP screen spline. (do not re-use spline when rescreening)

Step 7

Screen Trimming

- Run blade along the top edge of extrusion.

- Trim location is the same for both sides of the extrusion

- Use Caution: Aggressive or deep trimming will damage spline and/or weaken hold.

Watch the complete SNAPP screen installation process below

Other Information / Notes

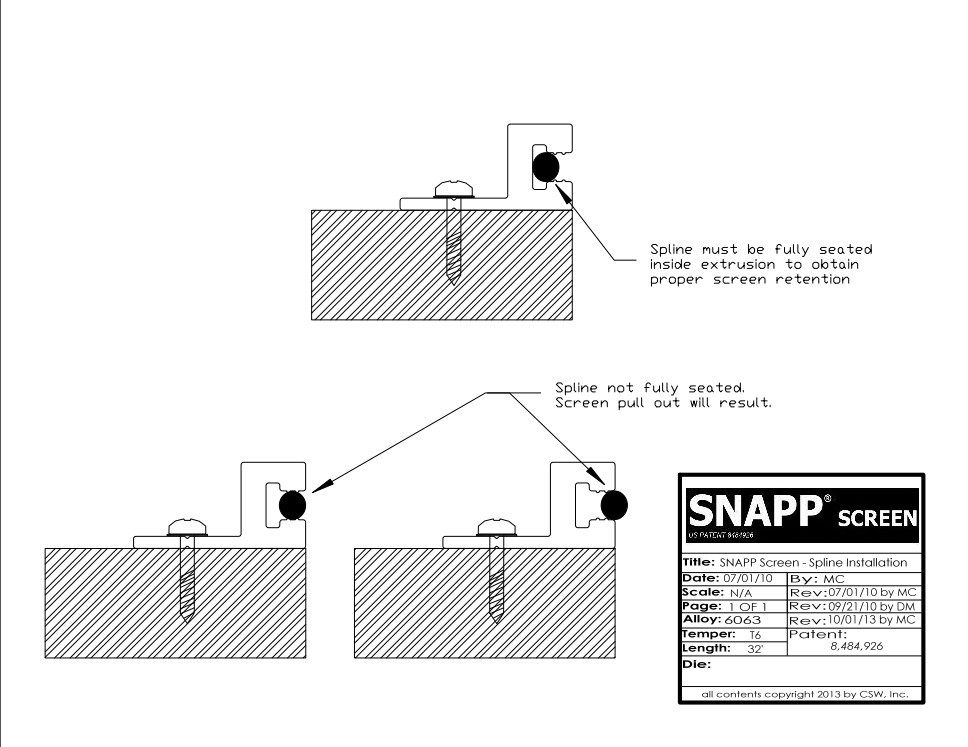

SNAPP screen spline (item: PF-014-500) must be used and fully seated within spline channel for proper hold. Use of other any other spline or failure to fully seat spline will result in screen pull out. Additionally, all spline tools are not the same, it is highly recommended that a SNAPP screen spline installation tool (item: TL13) be used for spline installation. (see web store for more information on each item)

– SNAPP screen is designed to be installed by an average person with common tools (The DIY’er).

– SNAPP screen is incredibly easy to repair if your screen material ever develops holes or tears. All you’ll need to do is pull out the SNAPP screen retainer spline and remove the screen material. Next, install new screen material and new screen retainer spline in the same frame.

– One of the greatest features of SNAPP screen is that it is specifically designed to be butted together. Opening width or height doesn’t matter with respect to stock extrusion size … just cut the extrusion as needed and butt pieces together. SNAPP screen is a zero waste product so every inch of product is usable.

– Aluminum SNAPP screen and PVC SNAPP screen extrusions are color matched so they can be used together whenever needed.

– SNAPP screen was specifically designed to be used with modern and super strong polyester screen materials. SNAPP screen will accept all standard polyester and fiberglass screening materials, most sunshade materials, thin (.008 or less) PVC plastic or films, and other fabrics. Additionally, while standard .011g (or thinner) aluminum can be installed, it is not at all recommended … Installation can be extremely difficult even if you are fully skilled in screen installation. Bronze, copper, stainless, etc are all too stiff and should be avoided completely.

Still Not Sure?

Jump over to our YouTube page and see what our great customers think about SNAPP screen and their completed DIY porch screen projects

Warning: Follow all common and accepted safety practices and ensure that you’re proficient in the proper and safe operation of any tool, equipment or procedures required to install SNAPP screen.

Warning: SNAPP screen is a “build in place” / “screen in place” insect screening system and will not provide fall prevention. Further, insect screenings only intended use is to reasonably stop insects from entering the covered opening. The misuse of insect screen may lead to injury or death. SNAPP screen will not stop persons, children, animals, or alike from falling out of or entering through the insect screen covered opening.